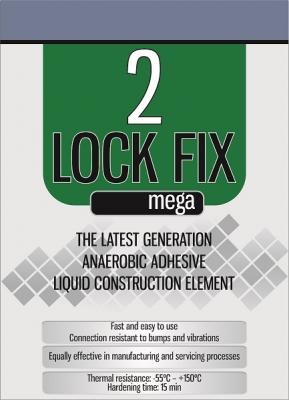

MEGA LOCK FIX anaerobic adhesives are single-component liquid plastics that harden permanently into a mechanically and thermally resistant mass, once the oxygen supply is cut off and the adhesive is put in contact with the metal. Liquid anaerobic plastic adheres to external coarse areas of connected elements. A shaped connection resistant to bumps and vibrations is established, providing protection against water, oil, liquid fuels, gases and other chemical substances. MEGA LOCK FIX adhesives — so-called “liquid construction elements” — are state-of-the-art technology for secure connecting, sealing, fixing and protecting metal machine parts and components. They are equally effective in manufacturing and servicing processes. Easy to apply straight out of the packet.

MEGA LOCK FIX 2 is designed for locking threaded joints. It is especially useful in heavy load applications, e.g. for locking nuts on double-sided bolts in pump and engine housings. It is used also on other connected elements that require maximum durability.

USAGE

MEGA LOCK FIX 2 is an adhesive to protect threads, featuring a very strong adhesive bonding force. MEGA LOCK FIX 2 is designed for locking metal fastenings and thus protecting them against unscrewing under the influence of vibrations; it also prevents leakages from threads. MEGA LOCK FIX 2 is especially suitable for larger threaded locks, e.g. bolts, where maximum force is a must. It is not recommended to use the product in environments with the presence of pure or a high concentration of oxygen. The product should not be used in locations subject to contact with chlorine and other strong oxidizing agents.

Application method

1. The best results are obtained on clean surfaces, free from lubricating substances.

2. Apply a few drops on the bolt and nut.

3. Application and pressure according to requirements.

4. Shake before use.

5. Be careful not to touch the metal surface with the tip of the nozzle, as this may cause the opening to clog.

Disassembly

1. Heat up the bolts and nuts and then disassemble while hot.

* Type in the captcha |

|

| |